Ladle Refractory Maintenance

LVR provides ladle refractory maintenance using GOM-BDRE equipment to efficiently hot clean ladles, removing skulls and refractory material.

Wireless remote-controlled technology allows personnel to work safely at ground level, outside of an equipment cab, with a full view of the inside of the ladle.

LVR’s refractory maintenance service provides careful ladle hot clean and refractory lining removal, eliminating damage to the safety lining. The process typically takes less than one hour to complete.

We also provide porous plug removal, well block and upper nozzle punch out using precision bits.

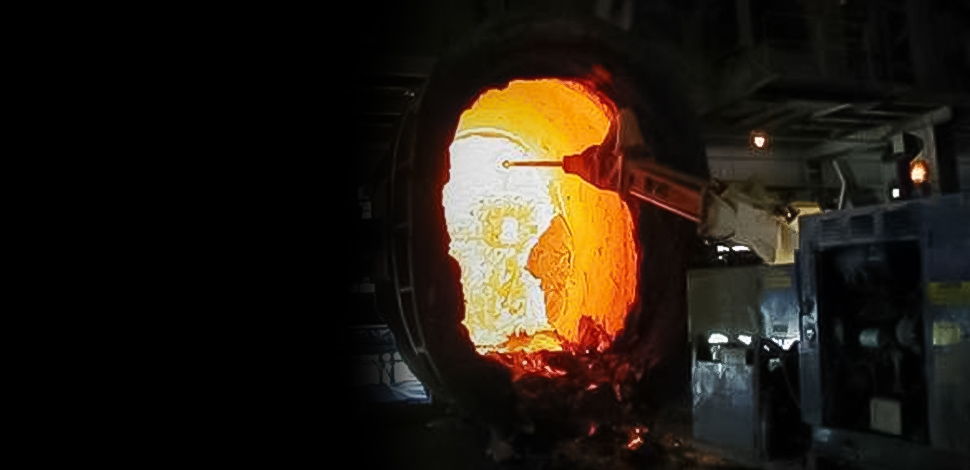

EAF Furnace Lining Patch or Removal

LVR provides furnace refractory lining patch and removal services using GEF-530 top mount machines and GOM-BDRE mobile equipment to accommodate electric arc furnaces with diameters from 10 to 35 feet and capacities up to 400 tons.

Wireless remote-controlled technology allows personnel to work safely from a secure location above the furnace, away from heat and falling debris. There is no need for personnel to enter the furnace at any time.

Careful, controlled material removal extends refractory life during furnace lining patches. The GEF-530 machine typically removes an entire lining in just six to eight hours depending on furnace tonnage, reducing furnace repair downtime significantly.