Major Relines & Minor Repairs

- Comprehensive furnace evaluation providing insight into furnace condition and technical recommendation for repairs

- Complete cleaning and maintenance repairs of burners, walls, and ports

- Complete Installation of precast shapes, brick, castable, ram, and shotcrete

- True end-to-end project management, including full refractory design services and dryout coordination

Repairs are accomplished sooner with immediate start of installation by the same personnel who performed the tear out.

Refractory Removal

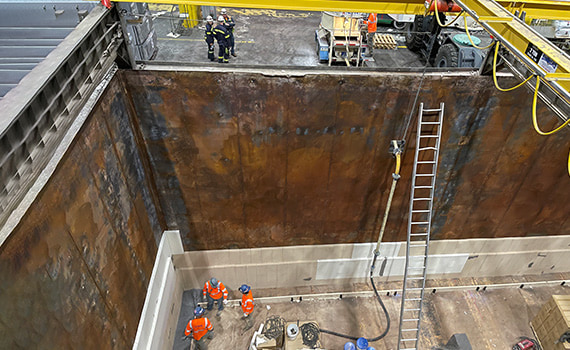

Our specially engineered demolition equipment is remote controlled and significantly improves worker safety. Eliminating hours of heavy manual labor through machine utilization.

- Precision refractory removal

- Placement of pre-cast shapes using mechanized equipment

Remote-controlled equipment remains onsite for the duration of the project.